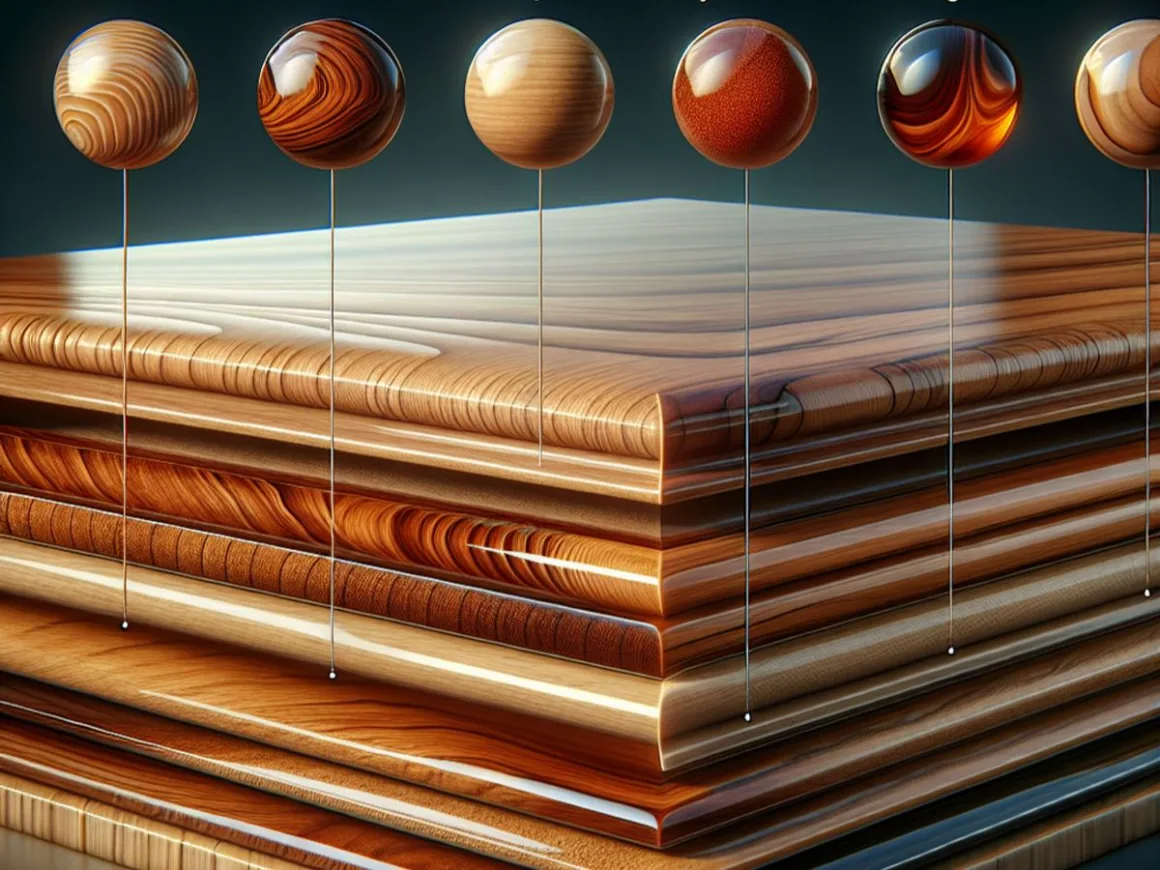

There are several different clear finishes used for wood finishing. Some of the popular finishes are Shellac, lacquer, polyurethane, and varnish. Each of these clear coats is used over stained wood, but they all have different properties.

Difference Between Varnish and Other Clear Coats

Varnish

Varnish is an oil-based clear coat that is thinned and cleaned with mineral spirits and is suitable for various projects.

Characteristics of Varnish

Drying Time:

Varnishes dry slowly, minimizing brush marks on large surfaces for a smooth finish. Quick-drying options like Quick-15 by Zinsser dry in about an hour, which is ideal for smaller projects or less-than-ideal conditions.

Durability:

Oil-based varnish forms a hard, durable surface resistant to abrasion and chemicals, perfect for high-traffic areas like floors and tabletops.

Adhesion:

The varnish offers excellent adhesion, preventing peeling or chipping. Proper surface preparation is crucial.

Yellowing Effect:

Oil-based varnishes can yellow over time due to oxidation and UV light, affecting light-colored stains. Consider this when choosing your finish.

Application Tips

Surface Preparation

- Cleaning: Remove dust, dirt, or grease with a clean cloth and mild detergent.

- Sanding: Sand the wood with progressively finer grits of sandpaper.

- Tack Cloth: Use a tack cloth to remove the remaining dust after sanding.

Application Tools

- Brushes: Use high-quality natural bristle brushes for oil-based varnishes; and synthetic for water-based.

- Foam Applicators: Ideal for smooth, even coats without brush marks.

- Rollers: Short-nap rollers are great for large surfaces.

Ventilation

- Work in a well-ventilated area.

- Use fans to circulate air.

- Wear a respirator mask if needed.

Multiple Coats

- Apply multiple thin coats rather than one thick coat.

- Thin the first coat slightly for better penetration.

- Lightly sand between coats with fine-grit sandpaper.

Drying Time Between Coats

- Follow the manufacturer’s drying time instructions.

- Be mindful of temperature and humidity, which can affect drying times.

By understanding these characteristics and application tips, you can achieve a durable, beautiful finish on your wood project.

Types of Varnish

Spar Varnish:

- Designed for Outdoor Use: Spar varnish is specifically formulated to withstand the harsh conditions of outdoor environments.

- Flexibility: This type of varnish remains flexible after drying, allowing it to expand and contract with the wood as temperatures and humidity levels change.

- UV Resistance: It provides excellent protection against ultraviolet (UV) rays, preventing the wood from yellowing or degrading over time.

- Ideal Applications: Perfect for exterior doors, window frames, and marine applications such as boat decks and railings.

Polyurethane Varnish:

- Synthetic Composition: Polyurethane varnish is a synthetic varnish known for its exceptional durability.

- Water and Chemical Resistance: Offers superior resistance to water, chemicals, and abrasion, making it ideal for high-traffic areas.

- Oil-Based Formulation: The oil-based version provides a warm finish and is highly durable but takes longer to dry and has a stronger odor.

- Water-Based Formulation: The water-based version dries faster, has less odor, and cleans up easily with soap and water. It is also more environmentally friendly.

Alkyd Varnish:

- Traditional Oil-Based Varnish: Known for its classic formulation that has been used for decades.

- Durability: Provides long-lasting protection with a hard finish that can withstand wear and tear.

- Warm Amber Tone: Imparts a warm amber hue to the wood, enhancing its natural beauty.

- Application Tips: Requires careful application with multiple thin coats to avoid runs and drips; typically needs longer drying times between coats compared to modern alternatives.

By understanding these characteristics and application methods, you can effectively use varnish to protect and enhance the beauty of your wood projects.

Shellac

Shellac is a versatile finish and sealer known for its fast-drying properties. It contains a naturally occurring wax that can repel some finishes applied over it, which necessitates the use of “de-waxed” versions if you plan to re-coat with various clear coats. Standard shellac should only be used under true oil-based varnishes to avoid compatibility issues.

Key Features of Shellac:

- Fast Drying: Allows multiple coats to be applied in a day, expediting the finishing process.

- Non-Yellowing: Unlike other finishes, shellac does not yellow over time. However, it does have a slight amber cast (clear bleached shellac) which can be minimized by applying thin and few coats.

- No Re-Wetting Stains: Shellac does not re-wet oil-based stains, unlike oil-based varnishes and polyurethanes. This ensures that your initial staining remains intact.

Application Methods:

Shellac can be applied in various ways:

- Brushing

- Rolling

- Spraying

These methods provide flexibility depending on the specifics of your project. Many professionals prefer shellac for field finishing due to its user-friendly properties.

Practical Benefits:

- Reversible with Alcohol: One unique aspect of shellac is its reversibility. If mistakes occur or refinishing is needed, shellac can be dissolved with alcohol.

- Speed: The quick drying nature allows for rapid build-up of coats, making it ideal for projects needing quick turnaround times.

Considerations:

While shellac has many advantages, it’s important to note that it will develop white spots if water stands on the surface for an extended period. To counteract this vulnerability, it’s often finished with an oil-based varnish on top.

“Shellac is truly a pleasure to work with,” many professionals attest, highlighting its efficiency and ease of use in various applications.

For more detailed information about shellac and its uses, see Shellac.

Polyurethane

Polyurethane is a popular choice for clear coats due to its durability and resistance to chemicals. Let’s break down the different types and their characteristics:

Oil-Based Polyurethane

Generally, these are oil-based modified clear coats with polyurethane. They offer several advantages:

- Durability: Very tough and chemically resistant.

- Finish: Provides a rich, warm glow to wood surfaces.

However, there are some downsides:

- Adhesion: Poor adhesion compared to other finishes.

- Drying Time: Dries slowly, requiring more time between coats.

- Yellowing: Tends to yellow significantly over time, which can be an issue for light-colored woods or projects where clarity is essential.

Water-Based Polyurethane

Water-based versions are available as well. These have their own set of pros and cons:

Advantages:

- Clarity: Less likely to yellow over time compared to oil-based options.

- Drying Time: Faster drying times, allowing for quicker project completion.

- Ease of Cleanup: Easier to clean up with just soap and water.

Disadvantages:

- Chemical Resistance: Generally less chemically resistant than oil-based polyurethane.

- Toughness: Not as durable, which might not make it suitable for high-traffic areas or surfaces that will face significant wear and tear.

Minwax Polycrylic

An alternative option is Minwax Polycrylic, a blend of polyurethane and acrylic. This product has specific benefits:

- Non-Yellowing: For the most part, it does not yellow over time, making it ideal for preserving the original color of your project.

- Application: I’ve used this one with faux finishes where avoiding yellowing was crucial, and I’ve achieved good results.

Note: While Minwax Polycrylic is effective in many scenarios, always research the specific product you intend to use if yellowing or other properties will impact your project.

For more detailed information about applying polyurethane, see Polyurethane.

Lacquer

Most DIY’ers are not going to use lacquer. Standard lacquers must be sprayed (there are some brushing lacquers, but they do not brush that well), smell very bad, and are extremely flammable.

Types of Lacquer

- Standard Lacquers: Require spraying for application, which can be cumbersome for home projects.

- Brushing Lacquers: Available but not particularly user-friendly as they don’t spread smoothly.

- Water-Based Lacquers: Minimize odor significantly but there are often better alternatives like acrylic and urethane finishes.

Advantages of Lacquer

The key strength of lacquer lies in its quick drying time and the unique ability of each coat to melt into the previous one. This melting property is also found with shellac, making lacquer an excellent choice for rubbing out finishes. This process involves sanding and polishing the final coat to achieve a smooth, glossy surface.

- Quick Drying: Allows for faster project completion.

- Melt-In Coats: Each new coat fuses seamlessly with the previous one, providing a uniform finish.

Disadvantages of Lacquer

While lacquer has its strengths, it also comes with several downsides that may deter DIY enthusiasts:

- Odor: Strong and unpleasant, making it less suitable for indoor projects.

- Flammability: Extremely flammable, requiring careful handling and proper ventilation.

- Chemical Resistance: Though more resistant than shellac, it still suffers from water spots (white rings).

Comparison with Shellac

Shellac offers many of the same benefits as lacquer but comes with fewer drawbacks:

- Odor: Much less offensive compared to lacquer.

- Application Methods: Can be rolled or brushed easily, offering more versatility.

- Chemical Resistance: While both finishes will show water spots, lacquer is generally more chemically resistant.

Given these factors, I have always opted for shellac over lacquer. The reduced odor and ease of application make shellac a more user-friendly option while still delivering a high-quality finish.

Bottom Line

Depending on what you are finishing, and how you intend to apply the finish, each of the common clear coats has its own strengths and weaknesses. Here’s a closer look at some key considerations:

- Speed and Quick Drying: If you’re working on a project that needs to be completed quickly, opt for finishes like lacquer or water-based polyurethane. These dry fast, allowing you to apply multiple coats in a shorter time frame.

- Chemical Resistance and Toughness: For surfaces that will endure heavy use or exposure to chemicals, oil-based polyurethane is your best bet. It’s renowned for its durability and ability to withstand harsh conditions.

- Ease of Application: Beginners or those seeking a user-friendly option might prefer shellac. This finish can be applied with a brush or roller, making it accessible for DIY enthusiasts.

- Odor Considerations: If working indoors or in poorly ventilated areas, choose finishes with low odor such as shellac or water-based finishes. These options are less likely to cause discomfort during application.

All these clear coats are designed for finishing wood, but selecting the right one depends on your specific needs and circumstances. By understanding the unique attributes of each type, you can make an informed decision that ensures both efficiency and quality in your woodworking projects.

FAQs (Frequently Asked Questions)

Varnish is an oil-based clear coat, thinned and cleaned with characteristics such as slow drying time, excellent adhesion, and potential yellowing over time. Other clear coats like polyurethane and lacquer have different compositions and application methods, each with its advantages and disadvantages.

Varnish has a slow drying time, which minimizes brush marks on large surfaces. It also offers excellent adhesion, preventing peeling or flaking. However, oil-based varnishes can be yellowed over time due to oxidation.

Surface preparation is important, including cleaning the surface of dust, dirt, or grease. High-quality natural bristle brushes are recommended for oil-based varnish application. Working in a well-ventilated area, applying multiple thin coats, and following the manufacturer’s drying time instructions are also crucial.

There are different types of varnish such as spar varnish designed for outdoor use, polyurethane varnish with a synthetic composition, alkyd varnish known for its classic formula, and shellac which is a versatile finish and sealer known for its fast-drying properties.

Polyurethane offers clarity and is less likely to yellow over time compared to oil-based options. However, it generally has less chemical resistance than other clear coats.

Lacquer is known for its quick drying time and can offer similar benefits to shellac. However, it requires spraying for application and comes with several disadvantages such as lower durability and chemical resistance.

2 comments

I’m refinishing a 1960’s Banjo. I’ve got it to the stain I want it. Some refinishers say to use Oil Based top coat. Would that be Shellac?

More than a little late, but……….

Shellac is not an oil based finish; it is alcohol based. For your purpose, it would not be very durable and would be susceptible to softening from skin oils. It has poor resistance to water and especially to alcohols.