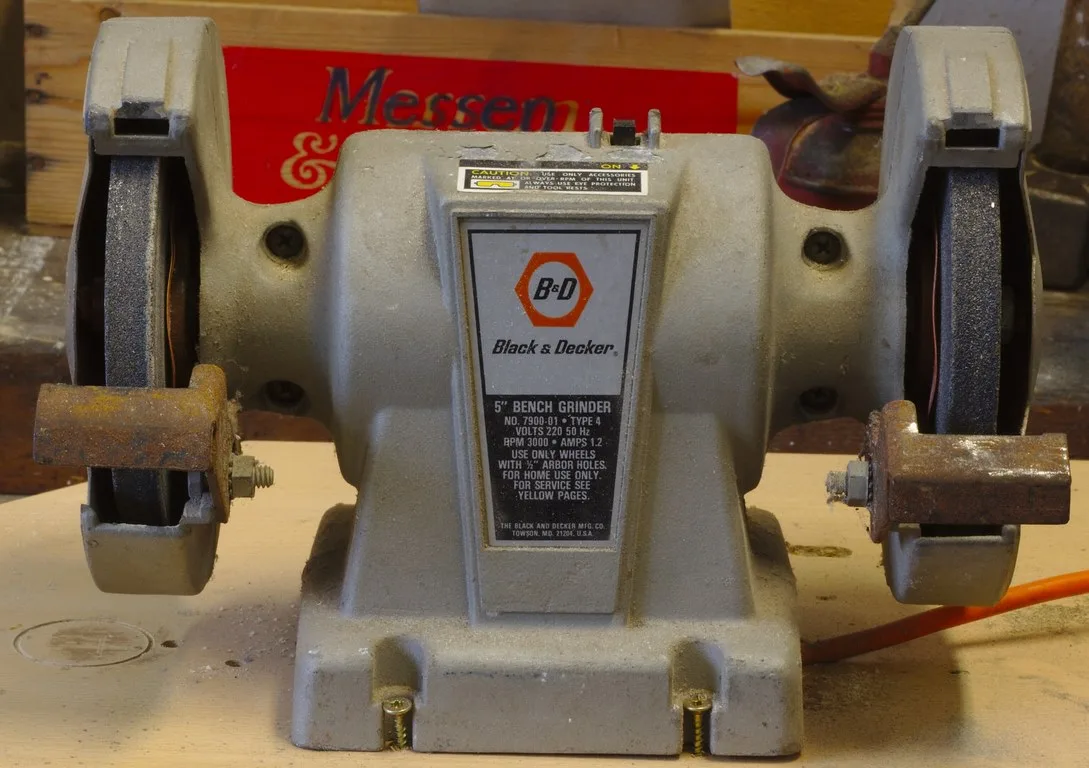

If you are looking for a product that can sharpen all your tools in one go then the Bench Grinder is the solution to your problem.

This leaves me with the question: what is a bench grinder and what exactly does it do?

For all the newbies who are reading this article, Bench Grinder is a device that can grind, cut, and shape metal.

I have used this device to mainly sharpen my knives and scissors. This awesome product can also do the opposite task of grinding down sharp edges and smoothen burrs off metal.

Before we dive into the types, technical details, and price range of the bench grinder, let me first take you through some of the safety procedures in using the product.

- The first and foremost safety practice is to ensure that the pedestal and bench grinders are secured on a solid surface.

Ensure all the guards are in place and secure before using a grinder.

- Ensure that the work rest has a gap of 1/8inch from the wheels.

- It is also crucial to have a 1/4inch gap with a tongue guard or a movable guard from the wheels.

- Before you turn on the grinder, it is advisable to manually spin the wheel to make sure it is spinning freely.

- Wear proper personal protective equipment such as eye, ear, and face protection along with safety boots and masks.

- Ensure that the wheels reach the maximum speed when turned on.

- Keep a bowl of water near the work area to cool the metal after grinding.

How Dangerous is a Bench Grinder?

The bench grinder, if not set and operated in the right way, can cause serious problems to the user.

For instance, most professionals recommend wearing tight clothes while using the grinder, on the contrary wearing loose clothes can increase the chances of getting entangled as the grinder wheel spins at great speed.

Similarly wearing gloves is strongly not advisable, as your fingers can get caught in the spinning wheel causing physical disabilities.

Likewise wearing protective gear such as safety boots, goggles, and respiratory masks is important when working with metal pieces as they cause a spark which can harm the internal organs of the user such as the lungs or sometimes it can even cause damage to your skin.

Improper use has shown that the bench grinders can explode and so it is recommended to stand far away from the side of the wheel for the first full minute before working on the machine.

Read Also:

Are Bench Grinders Worth Buying?

Despite its drawbacks and safety risks, I am an ardent fan of this device and to me, the bench grinders are worth buying.

The bench grinders are used across various applications ranging from carpentry to metalwork, this device is known for its multiple advantages.

Depending on specifications and features the bench grinders are priced starting from $50 to $3000.

Moreover, these products are classified depending upon the type of work it does.

Some of the best bench grinders that are worth buying are Ryobi GIDDS2-3554576 Bench Grinder, the product that I consider as the most affordable for newbies starts at $70 with a good set of features and specs.

I have rated Dewalt DW758 Bench Grinder as one of the best products overall.

This branded Bench Grinder is pretty expensive with a starting price of $137 and can get costlier as the accessories are added up.

I had reviewed the Delta Power Tools Variable Speed Bench Grinder, and to be honest, it is one of the best in the variable speed category.

If you consider the advantage of variable speed it brings to the table along with user-friendly features, its price range starting from $150 looks very reasonable in the category.

If you are looking for something strong, sturdy, and professional then Jet JBG-8W Bench Grinder, in my opinion, stands on top of the list especially for those who are serious about grinders and grinding as a profession.

The product is priced at $339 which is a bit expensive, but considering its professional use this product is worth the buy.

For those looking for more details on the above-said products, a complete review of these tools is available on this website Toolsterritory.com.

What Material Should Never be Ground on a Bench Grinding Wheel?

Though the purpose of this tool is to grind various metals, it has got restrictions when it comes to the choice of materials.

Before you start working with the grinder, I suggest you take some time to select the right wheel for the purpose as there is no one size fits all approach.

I strongly recommend against using materials that the wheel is not designed to handle. Materials such as sand wood, plastic, and other non-metallic substances.

These fine materials can get stuck in the wheel pores and later expand due to the heat produced during grinding. This can cause the expelling of the wheel material causing physical injury.

I usually perform a safety check wherein I spend some time trying to know and understand the type of wheel used and whether it is suitable for the work material before proceeding to operate the grinder.

What are the Types of Bench Grinders?

The bench grinder can be categorized according to the design, type of wheel, and grit used.

For those readers who want to know the different types of grinders based on design.

In this article, I would like to give an overview of the bench grinder based on the type of wheel used in the product.

There are five types of grinder based on their type of wheel. Let’s see them in detail.

1. Straight Wheel Grinder

This type of grinder is the most common in the market, and hobbyists like me usually use this tool for sharpening objects such as chisels, knives, etc.

A straight wheel grinder is best suited for surface grinding as well as cylindrical and centerless grinding.

2. Tapered Wheel Grinder

In this type of grinder, you can observe that its wheel is designed in such a way that it narrows towards edges making it ideal for light works such as sharpening the gear teeth or grinding threads.

3. Saucer Wheel Grinder

As the name suggests, the wheel is disc-shaped and consists of composite materials that are suitable for abrasive machining operations.

A saucer wheel grinder is mainly used for sharpening the saw blades.

4. Cylinder Wheel Grinder

This type of grinder comes with a hollow wheel to suit large materials. A cylinder wheel grinder is best if you want to sharpen a huge metal sheet in one go.

5. Diamond Wheel Grinder

As the name suggests, the wheel is normally lined with diamond bits. The diamond wheel grinder is capable of sharpening and cutting some of the hardest materials such as concrete and gemstones.

Conclusion

Overall, bench grinders are very useful when it comes to shaping and grinding, but I recommend the readers to choose the grinders wisely depending on their needs, the kind of materials that need to be cut or shaped, and of course, the budget.

Irrespective of the grinders you buy, I emphasize to the reader to practice the safety procedures with utmost priority.