Food production is a complex process that involves a variety of different machines and equipment. Proper lubrication is crucial to ensure that these machines run smoothly and efficiently and to prevent downtime and costly repairs.

However, lubrication can be time-consuming and labor-intensive, and it can be difficult to know which lubricant to use and how to apply it correctly. This article will discuss seven tips for simplifying food grade conveyor chain lubrication production through effective chain lubrication.

1. Use the Right Lubricant

Choosing the right lubricant is crucial to ensure that your chains are properly lubricated and protected. Various lubricants are available, each with its own properties and suitability for different applications. For food production, it is important to use a food-grade lubricant that is safe for use in areas where food is processed.

2. Lubricate Regularly

Regular lubrication is essential to keep chains running smoothly and to prevent wear and tear. It is important to establish a regular lubrication schedule and stick to it, to ensure that your chains are always properly lubricated. This can be done on a weekly, monthly, or even daily basis, depending on the type of machinery and the amount of use.

3. Clean the Chains Before Lubricating

It is important to clean them thoroughly before lubricating them. This will remove any dirt, dust, or other contaminants that may be present and will ensure that the lubricant can penetrate the chain and provide maximum protection. A simple cleaning solution, such as soap and water, can clean the chains.

4. Use the Right Amount of Lubricant

Applying the right amount of lubricant is crucial to ensure that your chains are properly lubricated without wasting lubricant. A general rule of thumb is to apply lubricant until it drips off the chain. This will ensure that the chain is fully lubricated and that the lubricant can penetrate all the moving parts.

5. Apply Lubricant to All Points of Contact

It is important to apply lubricant to all contact points on the chain for proper lubrication. This includes the pins, bushings, rollers, and the inside and outside of the chain links. This will ensure that all moving parts are properly lubricated and protected.

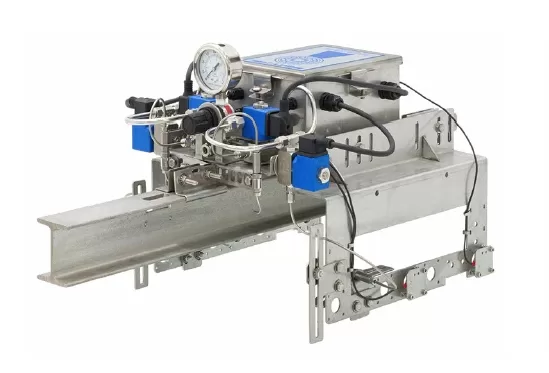

6. Use Lubricant Applicators

Lubricant applicators can make lubricating your chains much easier and more efficient. These tools can apply lubricant to specific points on the chain and help ensure that the lubricant is applied evenly and in the right amount.

7. Monitor Chain Wear

Regularly monitoring your chains’ condition can help identify any potential issues before they become serious problems. This can include checking for wear and tear, as well as looking for signs of rust or corrosion. If any issues are identified, they should be addressed as soon as possible to prevent downtime and costly repairs.

Conclusion

In conclusion, proper lubrication ensures that food production machinery runs smoothly and efficiently. By following these tips for chain lubrication, you can simplify the process of lubricating your machinery and help to prevent downtime and costly repairs.

Regular lubrication, using the right lubricant, cleaning, applying the right amount, applying lubricant to all points of contact, using lubricant applicators, and monitoring chain wear are all important steps that can help to keep your food production running smoothly.