Reviewed by: Ricky McLain, P.E., SE — mass-timber structural engineer and advisor known for advancing modern timber design, code education, and practical best practices for real-world projects.

Designing a home isn’t just picking walls and windows—it’s shaping how your days actually flow. That’s why Custom timber frame homes keep winning fans: you get the romance of exposed beams and the quiet, comfort, and durability of a modern, high-performance envelope.

For planning context on HouseSumo, see new-build budgeting tips, our farmhouse plan walk-through, permit steps in custom projects, and contractor-vetting questions (used once each; referenced later as “linked above”).

What “Timber Frame” Really Means (vs. Post-and-Beam)

In a timber frame, posts and beams are connected with precision mortise-and-tenon joinery locked with wood pegs. The connections are strong enough to leave exposed—and beautiful enough to make the structure the showpiece. Post-and-beam homes, by contrast, typically rely on metal plates/fasteners; still great, just a different craft story.

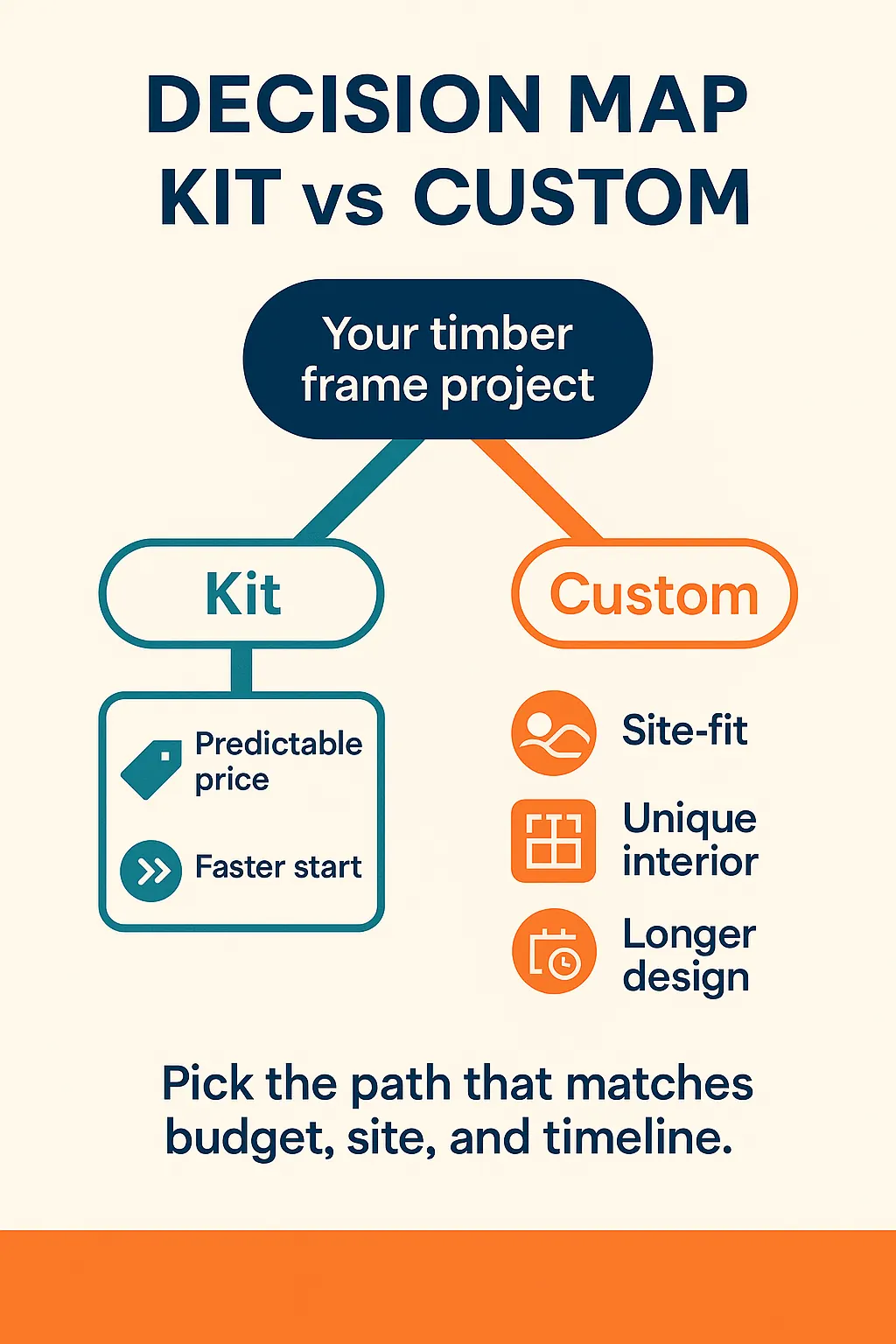

Kit vs. Fully Custom: What Fits Your Budget & Timeline?

A kit/package uses a pre-engineered frame and a standard enclosure (often SIPs), which reduces decisions and speeds pricing. A fully custom route lets you tailor spans, curves, and detailing to your site and lifestyle—more design time up front, with the payoff of a one-of-one interior and excellent day-to-day flow.

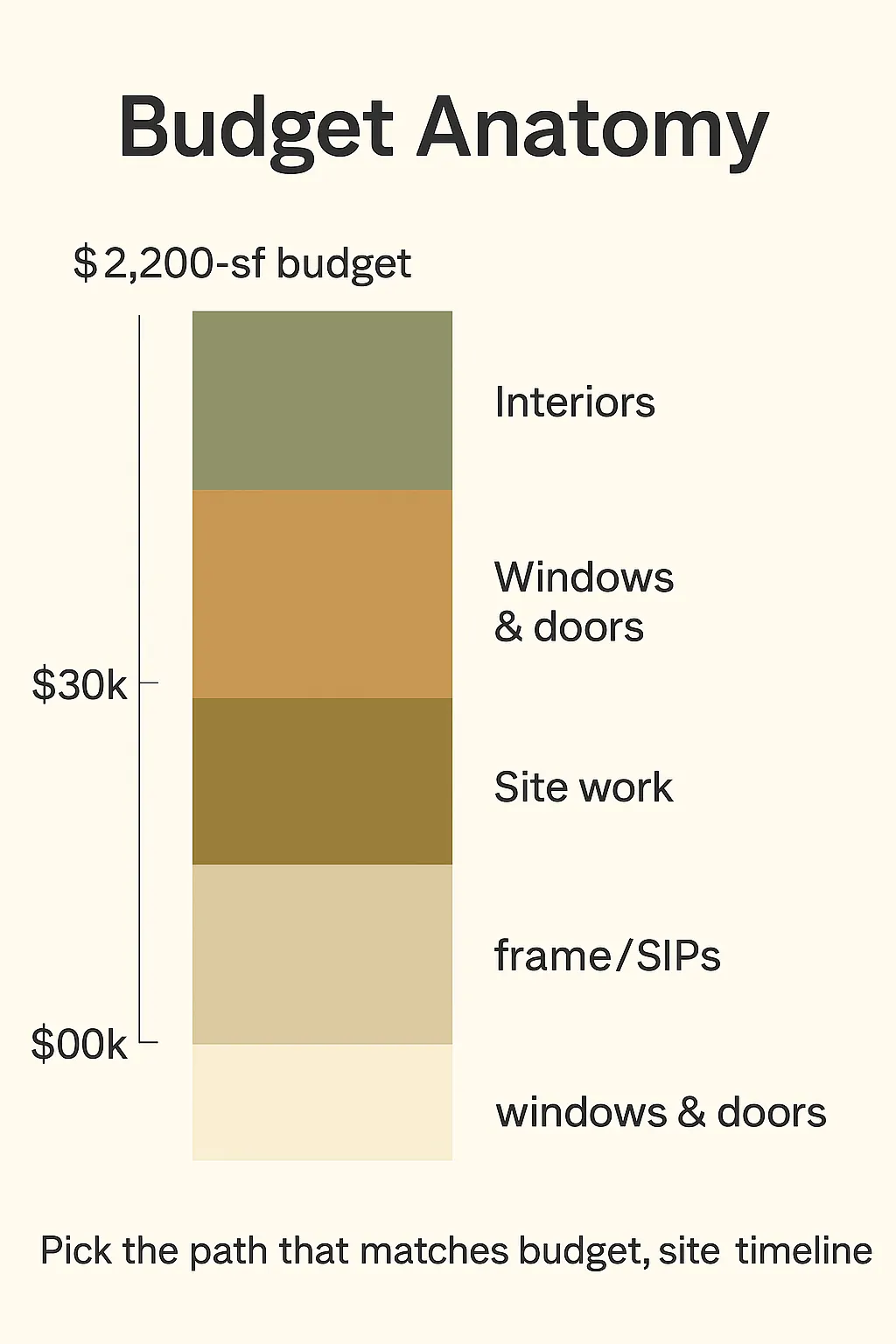

Budgeting Basics (Architect Fees, Realistic PSF Ranges & Allowances)

Architect + engineering fees. Custom residential work is commonly billed hourly or as a percentage of construction cost. The AIA explains why fee structures vary with deliverables and complexity, while HomeAdvisor’s current data gives homeowner ballparks (often ~8–15% of construction cost and ~$125–$250+ per hour depending on scope and market). See AIA fee guidance and HomeAdvisor’s 2025 architect cost page for details.

Per-square-foot reality. Finished timber-frame homes (frame + enclosure + interior finishes) often land around $200–$400+ per sq ft, while a frame + SIPs package alone commonly runs $150–$170 per sq ft (package cost, not turnkey). Treat these as ranges: glazing, site work, and cabinetry swing totals quickly.

Pro tip: Build a one-page allowance sheet (species, finish level, window package, SIP thickness, lighting tier). It prevents “death by a thousand changes.”

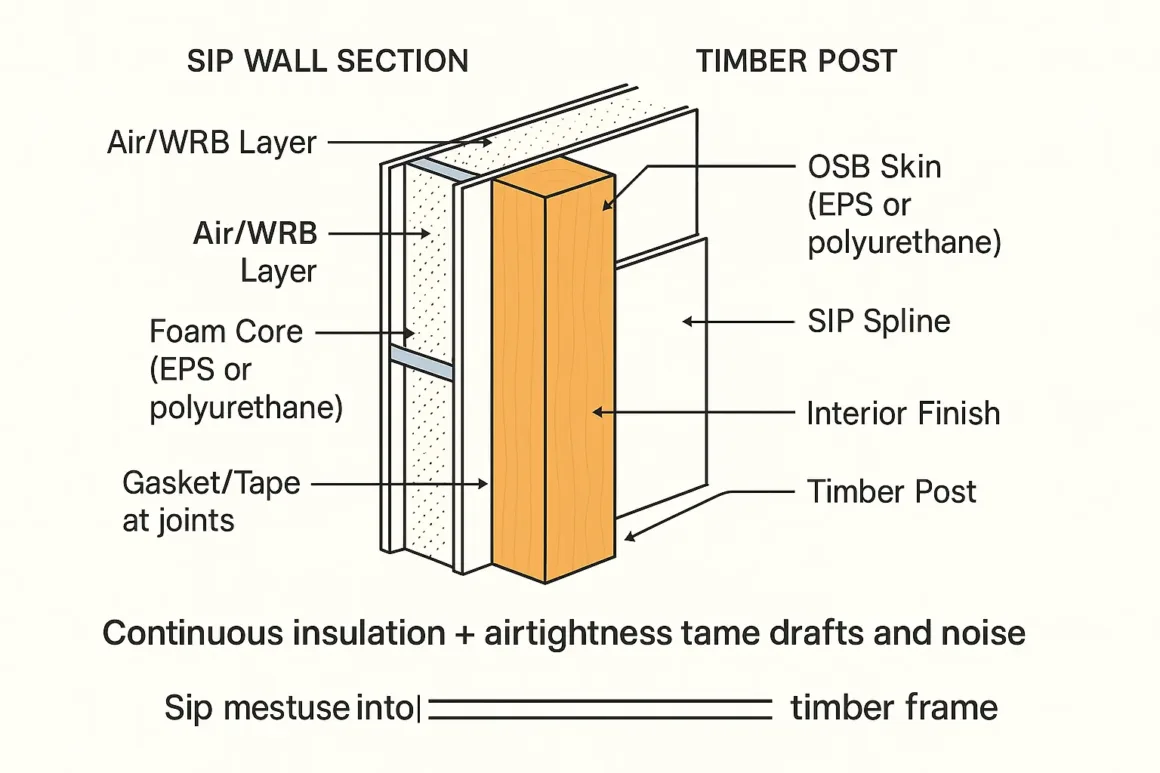

Comfort & Efficiency: Why Many Timber Frames Use SIPs

A timber frame doesn’t dictate the enclosure. Many owners choose SIPs (Structural Insulated Panels) because they provide continuous insulation, excellent airtightness, and minimal thermal bridging—the three ingredients of quiet rooms and steady temperatures. For a clear building-science overview, see SIPA’s “What are SIPs?” and WBDG’s SIP resource, which also discusses labor/waste advantages versus conventional assemblies.

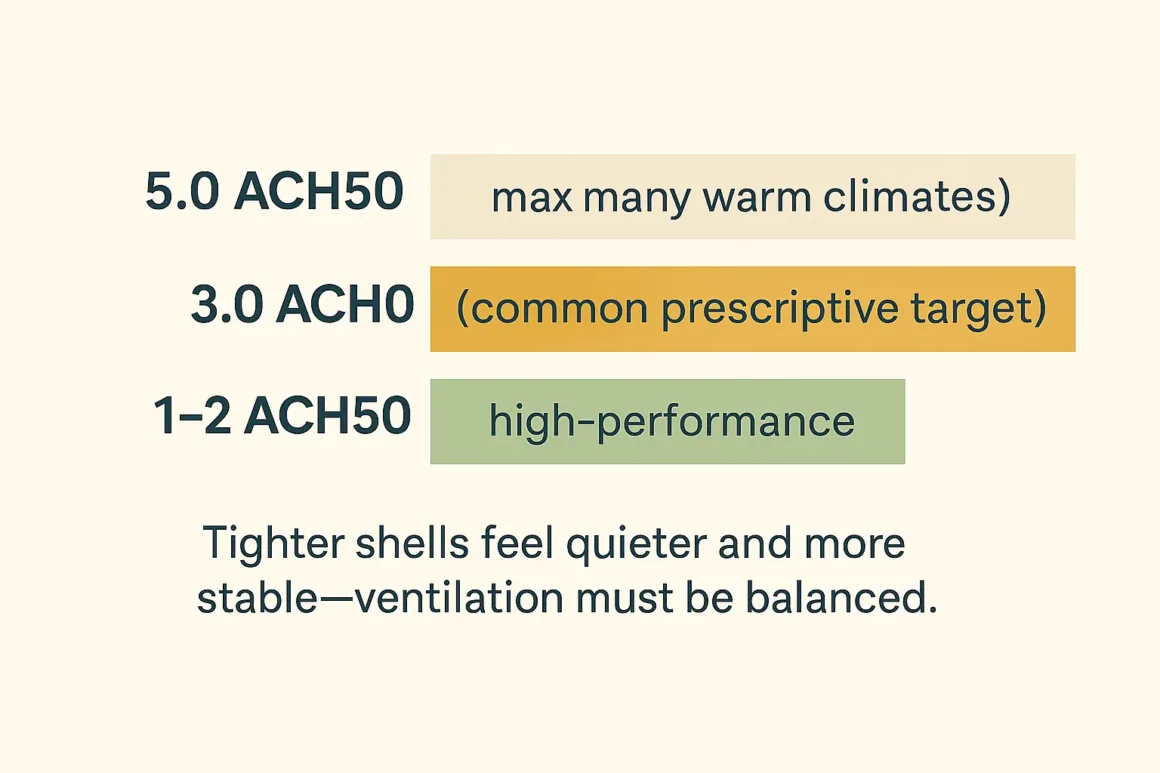

Airtightness matters. The U.S. Department of Energy notes that controlling air leakage is critical for efficiency, durability, comfort, and indoor air quality; use a whole-house approach that coordinates the air barrier, insulation, moisture control, and ventilation—see DOE Energy Saver on air sealing and air-sealing new construction.

Code testing targets. Many jurisdictions enforce blower-door testing with typical maxima around 3.0 ACH50 in colder zones and 5.0 ACH50 in warmest zones; the ICC code brief summarizes the 3/5 ACH50 limits, while the 2024 IECC determination analysis shows movement toward lower prescriptive leakage in some zones—confirm your local adoption before you budget. See ICC brief and 2024 IECC analysis.

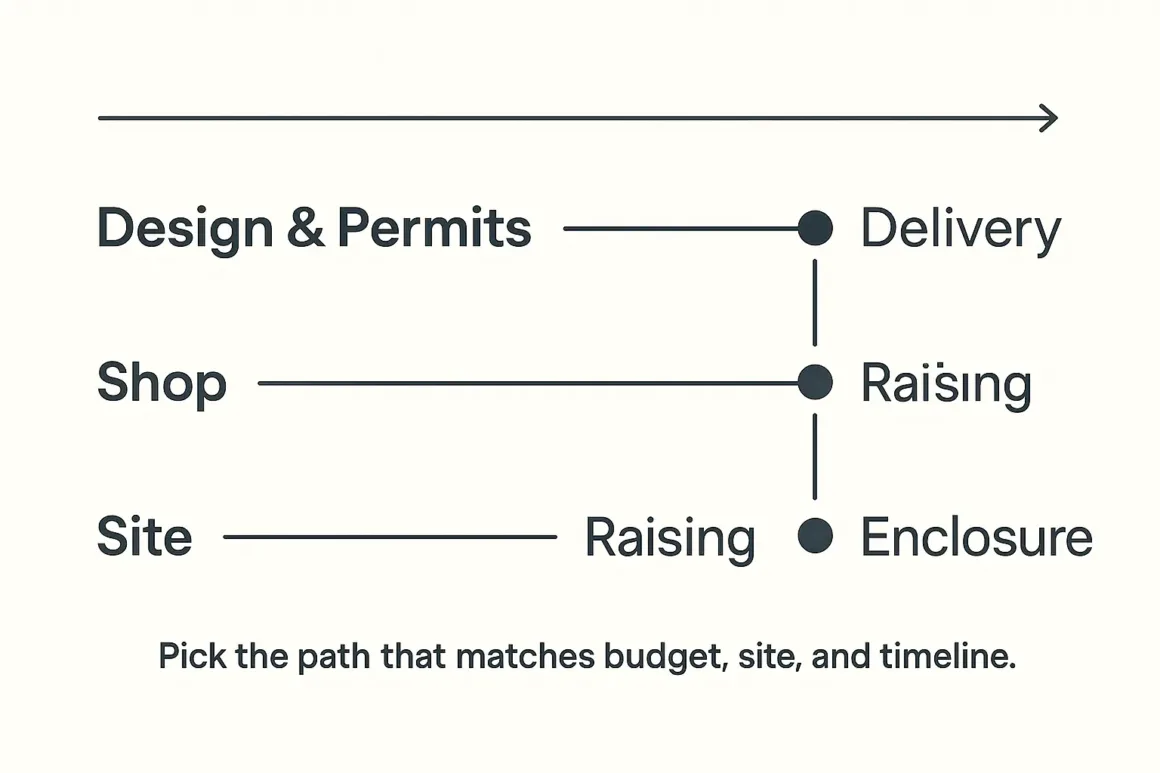

The 6-Step Process: From Idea to Raising Day

- Vision & constraints — lifestyle, views, sun, wind, snow loads, codes, budget bands.

- Schematic design — room adjacencies, spans, glazing, massing.

- Engineering & permits — member sizing, connections, energy-code submittals, site plan (use the permit guide linked above).

- Shop-fabrication — timbers are cut, test-fit, and finished under cover.

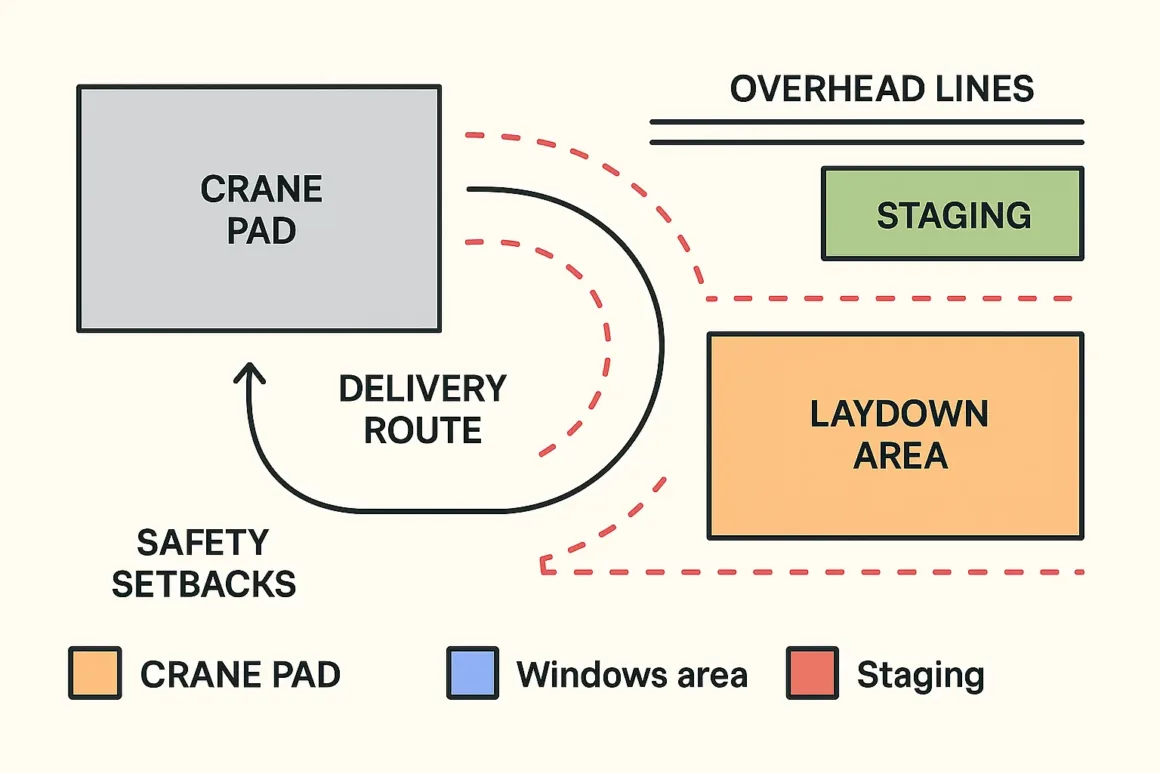

- Delivery & raising — with a ready site and good weather, many frames raise in ~5–10 days; schedule crane days early (lean on the contractor-vetting list linked above).

- Enclosure & finishes — SIPs or alternative envelope; rough-ins; windows/doors; interior finishes.

Craft You Can See (Joinery, Species, Finishes)

Joinery choices read like jewelry for the structure; Douglas-fir brings warm grain and strength, oak leans traditional and hard, hemlock/spruce keeps tones lighter. Finishes range from clear oils that celebrate grain to whitewash for bright, contemporary interiors—choose low-VOC for healthier indoor air.

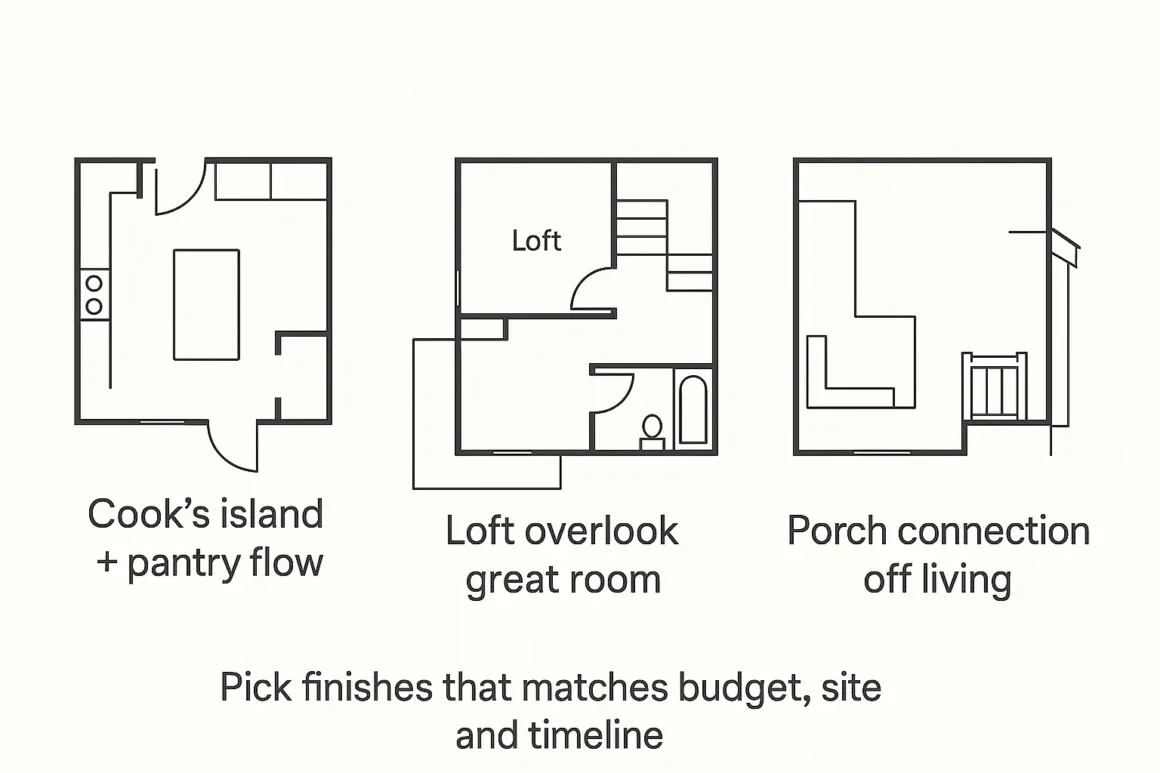

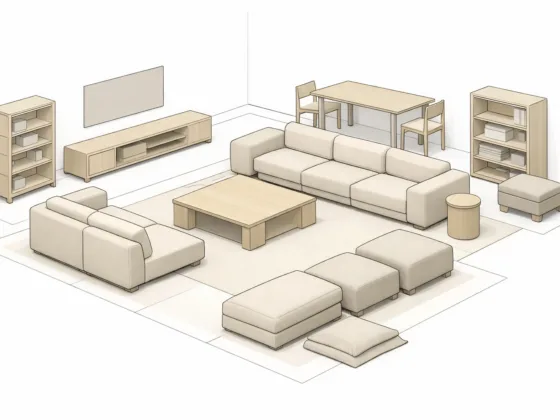

Layouts That Fit Real Life (Three Quick Personas)

The Cook’s Great Room has a 12–14′ working island, a walk-through pantry, and south-facing glazing for daylight from coffee to cleanup; skim the budgeting tips linked above, then commit to a short list of must-haves. The Reader’s Loft keeps a compact footprint with an open great room below and a quiet eyrie above. Indoor–Outdoor Hosts pair a modest footprint with a screened timber porch off the great room; a SIP roof hushes rain.

Permits, Inspections & “No-Surprise” Scheduling

Expect engineering for spans, seismic/wind/snow, and energy-code compliance. Map inspection checkpoints early, schedule crane days with your builder and utilities, and consolidate roof penetrations so your best solar array area stays clear; bundle these decisions in the permit set so you aren’t revising on the fly.

FAQ (People Also Ask)

Is a timber frame home more expensive than conventional?

Usually a little, because you’re paying for visible craftsmanship and large structural timbers. The final price is driven by choices: long open spans, lots of glass, curved braces, and premium kitchens push costs up, while simpler geometry, right-sized windows, and disciplined finish selections keep budgets in check.

How much does a timber frame home cost per square foot?

Think in ranges rather than one number. Many finished homes fall somewhere in the low-to-mid hundreds per square foot, with higher specs and tricky sites climbing from there. The biggest swing factors tend to be site work, window and door packages, and kitchen/bath finishes—each can shift totals more than people expect.

How long does it take to build a timber frame home?

Picture three phases. Design and permits take a few months, longer if you iterate heavily. Shop fabrication runs several weeks while the timbers are cut, test-fit, and finished under cover. On site, the frame often goes up in about a week, and then the enclosure and interior work carry the project to the finish line over the next few months.

Are timber frame homes energy-efficient?

They can be excellent when the shell is handled thoughtfully. Tight air-sealing, continuous insulation, and balanced ventilation do most of the comfort work. Many owners pair the frame with panelized enclosures to reduce drafts, stabilize temperatures, and quiet the interior.

Do I need an architect or engineer for a timber frame?

For custom designs, yes. An architect translates how you live into a plan that fits the site, while a structural engineer sizes members and connections so the frame performs under wind, snow, and seismic loads. Even kit packages typically require local engineering and permitting to match your jurisdiction and climate.

What are the disadvantages of timber frame homes?

Expect a modest premium over basic stick-built, some logistics for cranes on tight or steep lots, and extra attention to sealing around penetrations so the shell stays airtight. None of these are deal-breakers, but they deserve a line in the schedule and budget.

Will a timber frame last a long time?

Yes, with thoughtful detailing and ordinary maintenance. Heavy timbers are robust; the real enemy is unmanaged water. Keep bulk water out, let assemblies dry, and refresh finishes before they fail. Do that, and the structure repays you with decades of service.

Are timber frame homes good for very cold or very hot climates?

They are, provided the enclosure is tuned to place. Cold climates reward airtight shells, continuous insulation, and right-sized mechanicals. Hot-humid zones call for moisture control, shading, and balanced ventilation. Dry, high-altitude sites often benefit from careful solar-gain management and night-cooling strategies.

Can I buy a kit instead of going fully custom?

Absolutely. Kits give predictable pricing and faster timelines. Go fully custom if the lot is challenging, if you want long clear spans or dramatic curves, or if you’re aiming for a very specific interior feel that a standard package can’t capture.

What maintenance do timber frames need?

Think light and regular rather than heavy and constant. Keep gutters clear, direct water away from the structure, check sealant where services pass through the envelope, dust interior timbers, and refresh exterior finishes on schedule. It’s closer to caring for fine furniture than living at a jobsite.

Conclusion

You don’t have to choose between character and comfort. A well-planned timber frame gives you both: sculpture you can live inside and a calm, efficient envelope tuned to your climate. Define how your days actually flow—light, circulation, storage—then set a realistic budget with clear allowances. Align the team, pick the right enclosure strategy, and lock inspections and crane days early. Do that, and raising day feels less like construction and more like your long-sketched home finally standing up.

- Byline: Written by Perla Irish, custom-home writer who has interviewed timber builders and energy raters since 2015.

- Reviewed by: Ricky McLain, P.E., SE — mass-timber structural engineer and advisor (LinkedIn linked at top).

- Last updated: September 13, 2025.

- Disclaimer: This guide is informational; always follow local codes and your licensed design professional’s advice.