Quick Answer: At the end of the day, ADU structural requirements are about three things: a foundation that won’t move on you, framing and connections that safely carry loads down to that foundation, and permit-ready plans stamped by a licensed structural engineer. Whether you’re planning a backyard cottage, a garage conversion, or an attached “granny flat,” getting a structural engineer involved early is what keeps your design, budget, and building permit all pulling in the same direction.

Overview: ADU structural requirements make sure your small second home sits on a stable foundation, carries roof and floor loads safely, and meets local rules for wind, earthquakes, and fire. When you pair a thoughtful layout with permit-ready structural plans from a licensed engineer, you cut down on plan-check surprises and end up with an ADU that feels solid, safe, and comfortable for the long haul.

ADU Structural Requirements: From First Sketch to Building Permit

If you’re looking at your yard and thinking, “Could I tuck a small home back there?” you’re not alone. Accessory Dwelling Units (ADUs) – sometimes called granny flats, in-law suites, or backyard cottages – have become one of the most popular ways to add useful space and long-term value to a property.

In places like California, the state is actively encouraging ADUs as part of the housing solution. The California Department of Housing and Community Development (HCD) even maintains a dedicated ADU portal with handbooks, examples, and policy updates.

But here’s the part that doesn’t show up on pretty Pinterest boards: an ADU isn’t just a “tiny house.” Structurally, it’s a small, fully fledged home that has to meet the same safety standards as any other dwelling on your lot. That’s where ADU structural requirements and a good structural engineer come into the picture.

This guide walks you through ADU structural engineering from early idea to building permit, so you know what to expect at each step and where it makes sense to invest in professional help.

What Actually Counts as an ADU?

Different cities have slightly different definitions, but in plain language an ADU is a self-contained home on the same lot as a primary residence. It has a place to sleep, cook, bathe, and live – all behind its own door.

You’ll usually see these main flavors:

- Detached ADU – a small house in the backyard on its own foundation.

- Attached ADU – an addition that shares at least one wall with the main house.

- Garage conversion ADU – turning an existing garage into conditioned living space.

- Basement ADU – finishing a lower level so it functions as a separate dwelling.

- Junior ADU (JADU) – a smaller unit carved out of the existing home, often under 500 sq. ft.

They may look very different on a plan, but the structural goals don’t change. You still have to carry gravity loads (people, furniture, snow), resist lateral loads (wind and earthquakes), and satisfy the building code your city or county has adopted.

If you’re leaning toward a basement ADU, it’s worth stepping back and looking at the bigger picture first. Guides like “Basement Conversion: Down Is the New Up” and how to transform a basement into a living space walk through light, moisture, and layout issues. Those decisions have a huge impact on how your engineer will approach underpinning, drainage, and reinforcement.

Core ADU Structural Requirements (The Stuff Inspectors Really Care About)

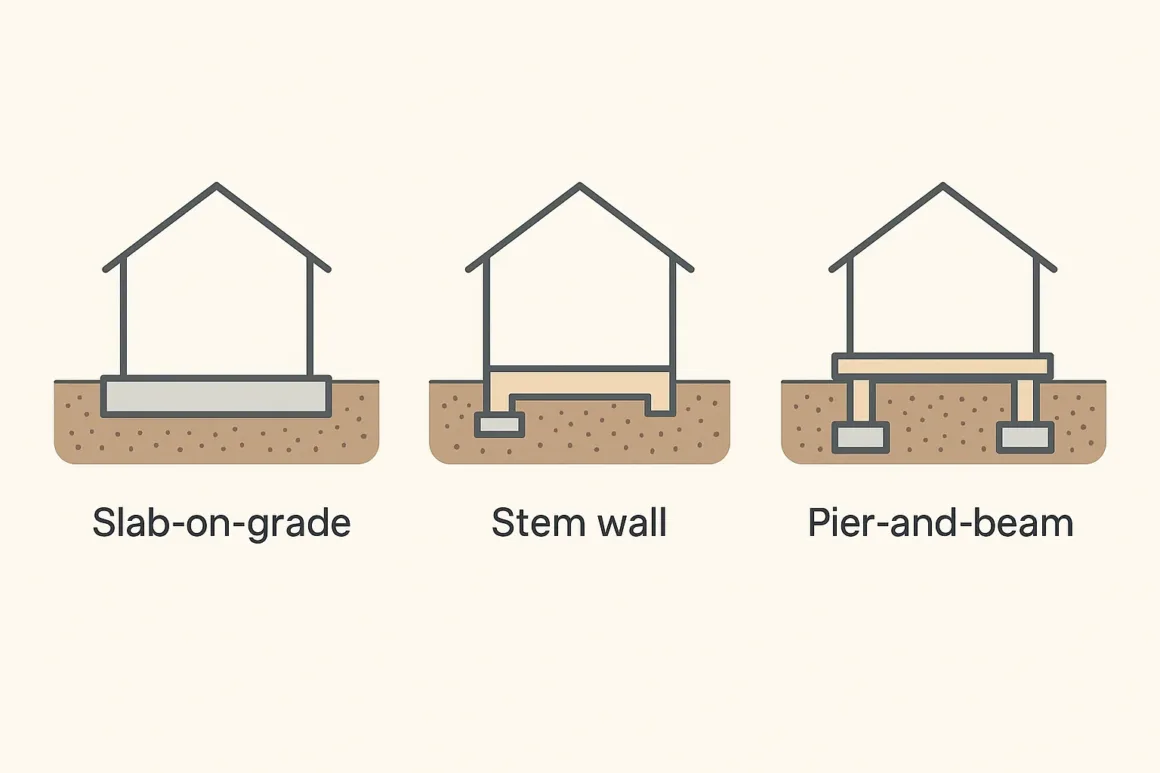

1. Foundations That Don’t Quit on You

Everything starts at the ground. Even a “small” ADU weighs a lot once you add up framing, roofing, finishes, and people.

Your structural engineer will pay close attention to:

- Soil conditions: Is the soil strong? Does it expand when wet? Are there signs of past settlement?

- Existing slabs and footings: For garage or basement conversions, are they thick enough, reinforced, and in good shape?

- Frost depth and moisture: In colder or wet climates, footings need to be deep enough and protected so they don’t heave or deteriorate.

- Drainage and slope: Water always wins if you ignore it. Sloped sites and retaining walls add another layer of structural thinking.

On a detached ADU, your engineer might recommend a thickened edge slab, shallow spread footings, or a pier and grade-beam system. With a garage conversion, the question often becomes: “Can we trust this existing slab?” Sometimes the honest answer is no, and you’re better off thickening, underpinning, or replacing it.

If your main house already has cracks, sloping floors, or sticky doors, an ADU is not the time to cross your fingers. Take a look at Housesumo’s foundation repair guide for a homeowner-level overview of what might be going on before you add more load.

2. Framing, Load Paths, and Roof Design

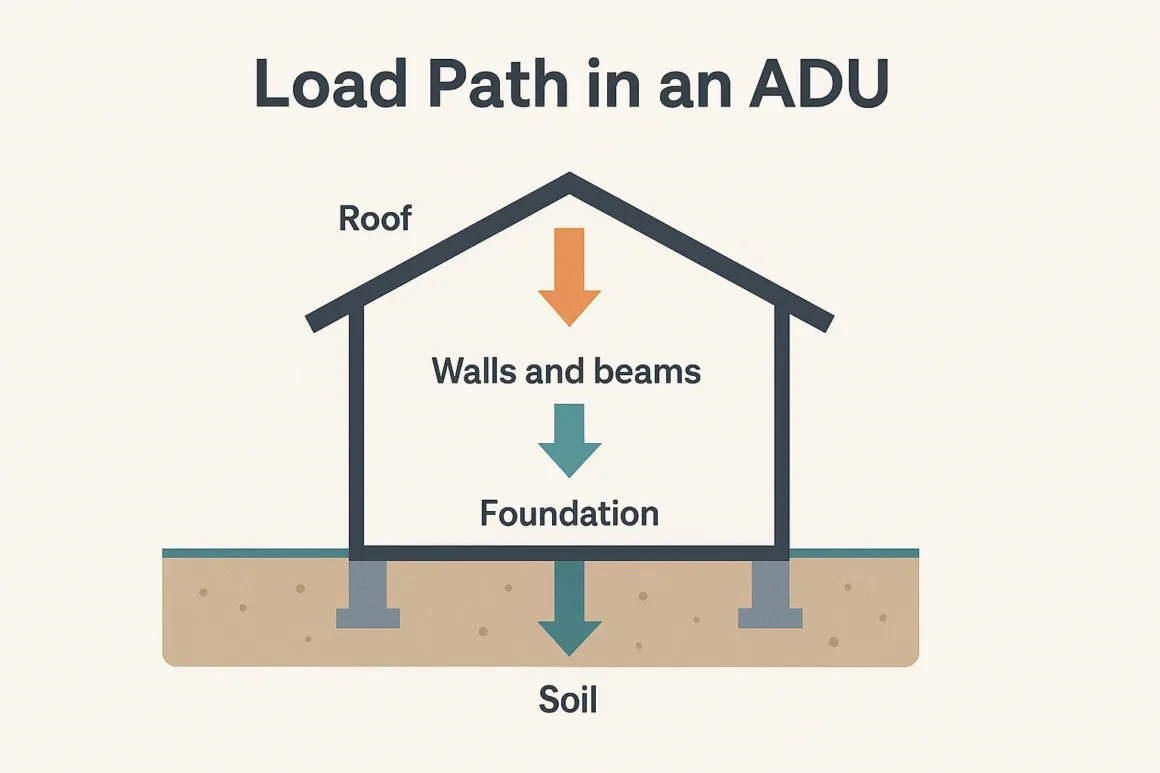

Once the foundation is sorted, the next question is: how does the weight of your ADU travel down to the ground without sagging, bouncing, or cracking things along the way?

Structurally, that comes down to a few core pieces:

- Floor framing: The joists, beams, and girders that carry people, furniture, and interior walls.

- Wall framing: Studs, headers, and posts – especially around big openings like sliders or former garage doors.

- Roof structure: Rafters or trusses, ridge beams, and roof sheathing that work together as a diaphragm.

- Connections: Anchors, straps, hangers, and hold-downs that turn a pile of lumber into one structural system.

Open-plan layouts, vaulted ceilings, and walls of glass can all be done. They just need real numbers behind them. That’s where a structural engineer earns their keep: sizing beams, checking deflection, and making sure nothing feels like a trampoline once you move in.

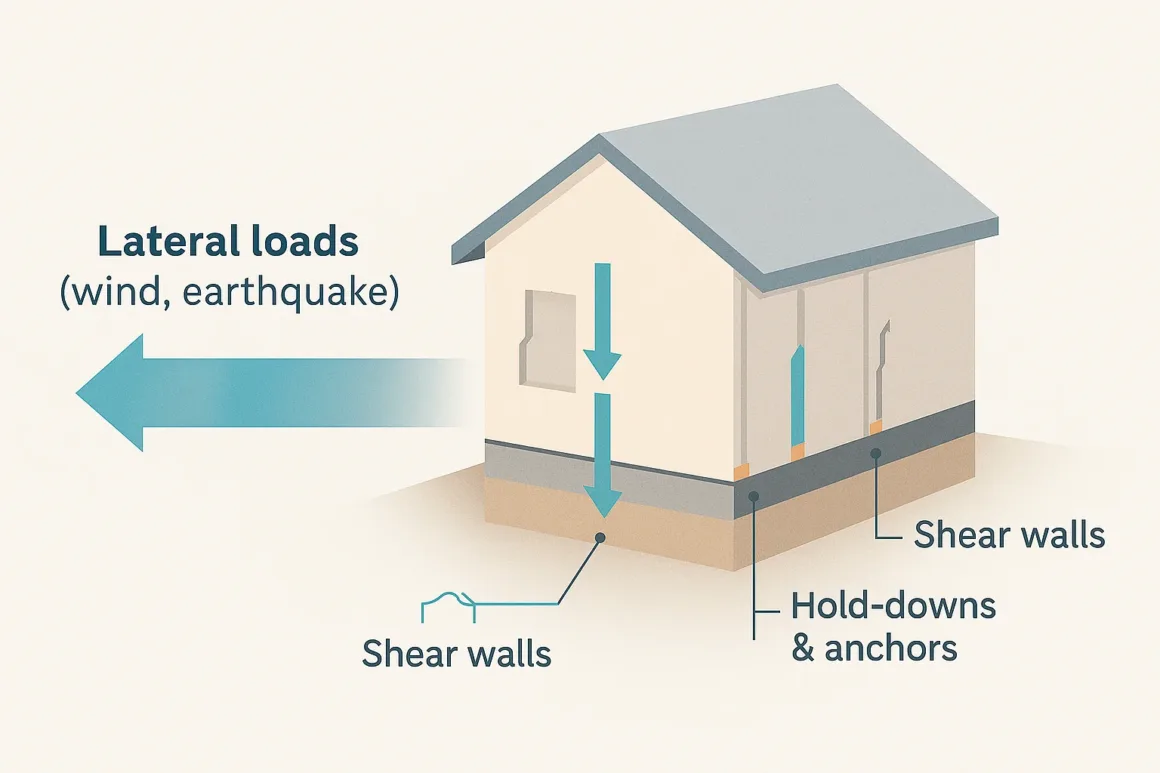

3. Lateral Loads: Wind, Earthquakes, and “Sideways” Forces

Gravity is only half the story. Building codes also expect your ADU to survive wind and, in many areas, earthquakes. The structural drawings will typically show:

- Shear or braced walls that keep the box from racking sideways.

- Hold-downs and anchor bolts that keep the walls fixed to the foundation.

- Roof and floor diaphragms (usually plywood or OSB) that collect lateral loads and deliver them to the walls.

- Connections at key joints – roof-to-wall, wall-to-floor, and floor-to-foundation – that create a continuous load path.

In seismic regions like much of California, the details get more specific. The updated California ADU Handbook is a helpful overview of what’s allowed and what tends to get flagged, even though it doesn’t replace an engineer’s calculations.

In cold, snowy places, the priorities shift. For example, builders in Vermont pay close attention to roof snow loads, frost depth, and uplift resistance. Firms like New Frameworks explain some of those nuances in their overview of ADU construction regulations in northern climates.

4. Fire Separation, Egress, and Other Life-Safety Details

Some “structural” decisions are really life-safety decisions in disguise. Your ADU plans have to account for things like:

- Fire-rated assemblies between the ADU and main home where required.

- Bedroom egress windows with enough clear opening and the right sill height.

- Stairs and guards with safe rise, run, and rail heights for lofts or two-story ADUs.

- Flood or wildfire overlays that drive choices like elevated foundations or ignition-resistant construction.

An experienced engineer and architect will coordinate these details so you don’t find out at framing inspection that your favorite window configuration isn’t going to fly.

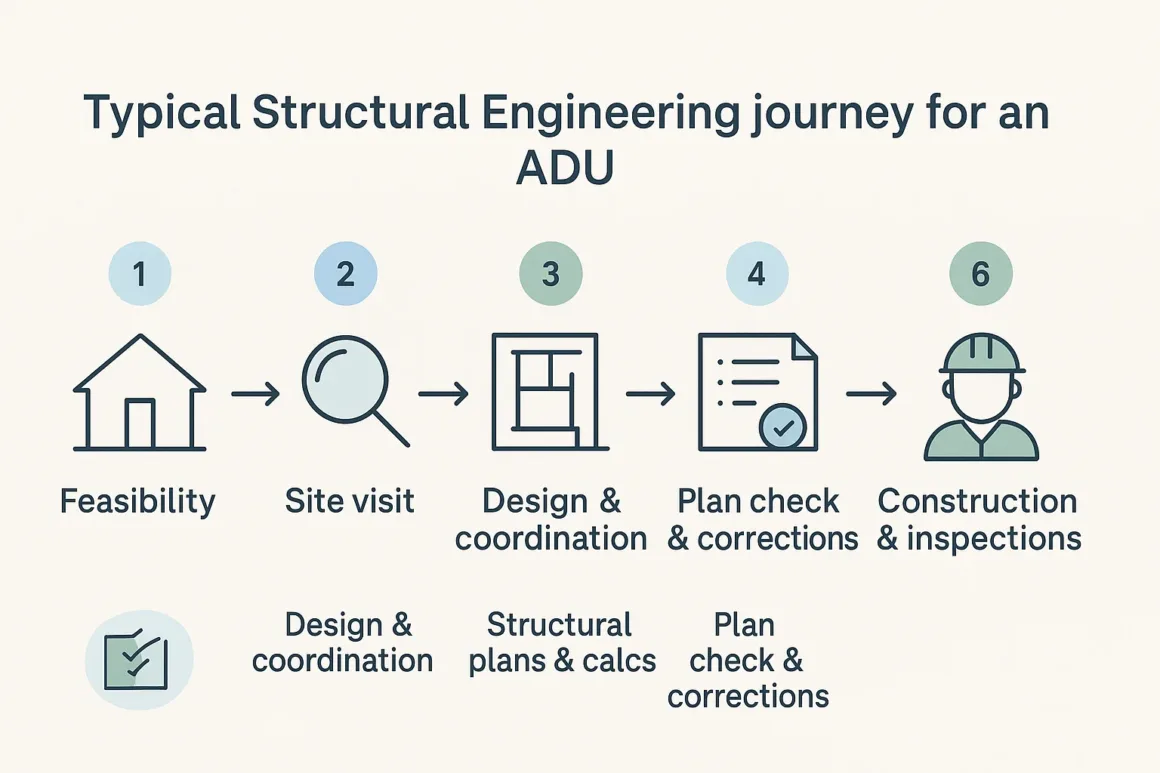

How the ADU Structural Engineering Process Usually Works

Most homeowners only go through this once, so it helps to know roughly what’s coming. Every project is a little different, but the structural side often follows a familiar arc. Once you’ve seen a few ADUs built from scratch, the pattern is hard to miss.

When homeowners talk about their projects afterward, two patterns come up again and again: the amount of work that happens before anyone swings a hammer, and how many plan-check comments focus on structure and life safety rather than paint colors or tile. Keeping that in mind going in makes the whole process feel a lot less mysterious.

Step 1: A Reality Check and Feasibility Review

Before anyone starts drawing detailed plans, it’s worth asking some blunt questions:

- Is an ADU allowed on your lot under current zoning?

- Are there overlays (historic, floodplain, wildfire, coastal) that will affect structure?

- Where could an ADU logically fit without wrecking access, light, or your existing yard?

A structural engineer from a firm like ProStruct can sit down with your survey, a rough sketch, and your city’s ADU handouts and give you honest feedback. Sometimes that’s a green light; other times it’s a reality check that saves you from chasing an impossible layout.

Step 2: Site Visit, Measurements, and Structural “Diagnostics”

Next comes the part where someone actually walks the site. During a typical visit your engineer will:

- Look at existing foundations, walls, and rooflines.

- Check for cracks, sloping floors, or other signs of movement.

- Review any old plans, soil reports, or permit history you have.

- Note utility locations, trees, retaining walls, and drainage paths.

Think of this as structural “diagnostics.” Just as a doctor wouldn’t prescribe treatment without an exam, your engineer doesn’t want to commit to a design until they understand what they’re working with.

Step 3: Early Design and Coordination with Your Designer

Once the site looks feasible, your structural engineer and designer or architect start trading ideas back and forth. This is where big decisions get made about:

- Foundation type (slab-on-grade, stem walls, piers, or something more specialized).

- Framing layout for floors and roofs, especially around big openings.

- Where to put shear walls so you’re still allowed nice windows.

- How to handle stairs, lofts, and ceiling heights without creating structural headaches.

Good coordination at this stage pays off later. It’s a lot cheaper to move a window on paper than to re-frame it after inspections.

Step 4: Detailed ADU Structural Plans and Calculations

When the basic layout is set, your engineer digs into the numbers and produces the sheets that will go into your permit set. A typical ADU structural package includes:

- Foundation plan with sizes, reinforcement, and anchor bolts.

- Floor and roof framing plans with joist, beam, and truss schedules.

- Shear wall and bracing layout with nailing, hold-downs, and strap details.

- Sections and details through tricky locations (stairs, big openings, transitions to existing structures).

- General structural notes and a calculation package covering gravity, wind, and seismic loads.

In many jurisdictions, some or all of these sheets must be stamped by a licensed Professional Engineer (P.E. or S.E.) to be accepted at plan check.

If you’re in California and want to see how a structural team turns a sketch into permit-ready ADU plans, it’s worth reviewing examples and case studies from firms that specialize in these projects.

Step 5: Submittal, Plan Check, and Corrections

Once your full set is ready (architectural, structural, mechanical, electrical, plumbing, energy), it gets submitted to your local building department. The staff there compares your ADU structural requirements against the adopted code and any local amendments.

Expect at least one round of “corrections” – questions or minor changes the plan checker wants to see. Your engineer is usually the one who answers those, clarifies details, and issues any needed revisions.

Many cities now publish very explicit ADU checklists or user guides. For example, the City of Oakland’s ADU guide spells out exactly which structural and architectural documents to upload for a single-family property. Checking resources like that early saves a lot of frustration.

Step 6: Construction Support and Inspections

Once the permit is in hand, the focus shifts to actually building the thing. Structurally, that usually involves:

- Foundation inspections before concrete goes in.

- Framing and shear wall inspections before insulation and drywall.

- Roof, stair, and guardrail checks where applicable.

- Final inspection to confirm the ADU matches the approved plans.

Field conditions don’t always match the drawings. When that happens, a quick call or email to your structural engineer is often the difference between a minor on-site adjustment and a full-scale design emergency.

Case Study: A 2-Bedroom Backyard ADU on a Narrow California Lot

To see how all of this comes together, imagine a common scenario: a 40-foot-wide lot in a California city, with a modest single-story home at the front and a sloping backyard behind it. The owners want a roughly 550 sq. ft. two-bedroom ADU for aging parents.

- Site constraints: Local rules allow a small detached unit with 4-foot side and rear setbacks, but the yard narrows near an existing retaining wall. That limits how wide the ADU can be and where doors and windows can go.

- Foundation solution: The soil report shows moderately expansive clay. The engineer designs a thickened edge slab with extra reinforcement and careful drainage details so seasonal moisture changes don’t push the structure around.

- Framing choices: Inside, the family wants an open kitchen-living area with a big patio door. To make that work, the engineer specifies a glued-laminated beam over the opening and a couple of carefully placed interior posts to keep spans reasonable.

- Lateral design: Because the rear wall is full of glass, most of the shear resistance comes from side walls. The drawings call out specific nailing patterns, hold-downs, and anchor bolts so those walls can safely resist wind and earthquake forces.

- Plan-check feedback: When the city reviews the plans, most comments revolve around stair and guardrail details for a small rear landing, and a fire-rating detail on the side closest to the property line. A quick clarification and one extra note from the engineer clear those issues.

- In the field: During framing, the contractor discovers an old, undocumented drain line where one footing is supposed to go. The engineer revises the footing layout and reinforcement so the line can be safely bridged without compromising support.

By the time the ADU is finished, the parents have single-level living, the main house has more breathing room, and the owners have a structure that’s been checked at every step – from soil to roof – instead of relying on guesswork.

Engineer’s take: On real projects like this, most of the “surprises” don’t come from wild design ideas – they come from things in the ground you can’t see on day one. Old drain lines, undocumented footings, or shallow utilities are exactly why your engineer will push for a careful site walk and good as-builts before locking in the final foundation plan.

Regional Regulations and Codes (With a California Tilt)

Every ADU project lives at the intersection of zoning rules and building codes. Zoning decides whether you can build and where the box can sit. The building code decides how that box has to perform structurally.

- Zoning and land use set maximum size, number of units, and where an ADU can go on the lot.

- Setbacks, height, and lot coverage tell you how tall and wide you’re allowed to build.

- Parking and access rules influence where doors, stairs, and sometimes even foundations land.

- Overlays – wildfire, floodplain, historic, coastal – can add extra structural and life-safety requirements.

In California, the HCD ADU portal and the updated ADU Handbook are two of the best starting points for owners and designers. They don’t replace engineering, but they do lay out the statewide framework your local plans examiner is working from.

Outside California, many states and cities are rolling out their own ADU guides and model ordinances. The pattern is similar: policy documents at the state or city level, and then structural details tied back to the International Residential Code (IRC) or International Building Code (IBC) with local amendments layered on top.

In practice, California ADU projects often hinge on a few local nuances that don’t show up in generic guides: how your city treats fire separation near property lines, whether local amendments bump up design wind or seismic loads, and how strictly plan checkers enforce details around stairs, guards, and egress. Those small differences are why owners in the same county can have very different experiences depending on their exact jurisdiction and site conditions.

What ADUs Actually Cost – and Where Structural Engineering Fits

Quick ADU Structural Cost & Engineering Estimator (Ballpark Only)

Use this simple calculator to get a rough feel for how construction costs and structural engineering might scale with your ADU size and complexity. These numbers are illustrative only – always confirm with local contractors, designers, and your structural engineer.

No two ADUs are priced exactly the same, but it helps to understand the ballpark before you fall in love with a particular design. Recent contractor surveys and cost guides suggest:

- Across many U.S. markets, turn-key ADU costs often land somewhere between $150 and $600 per square foot.

- In higher-cost states like California, detached ADUs frequently come in around $300–$600+ per square foot once you include design, permits, utilities, and site work.

- Garage conversions and attached ADUs can be cheaper per square foot, but they often require more investigative work up front.

On top of that, you’ll need to factor in soft costs like design, engineering, and permitting. Some California jurisdictions, for example, list ADU building permit fees in the rough range of $10–$12 per square foot, with some breaks for smaller units. Always verify the latest numbers with your building department.

Structural engineering is usually a relatively small slice of the overall budget, especially compared to site work and finishes. For a typical ADU, owners often see:

- Structural fees in the low-to-mid four figures for straightforward projects.

- Higher fees when there’s hillside work, complicated existing structures, or demanding seismic/wind conditions.

- Engineering costs that usually land in the 2–5% range of the total project budget, depending on scope.

Financing usually comes from a mix of cash, home-equity lines of credit, renovation loans, or cash-out refinancing. In a growing number of states, housing agencies also offer ADU-focused grants and low-interest programs aimed at increasing housing stock, so it’s worth asking your lender and local housing department what’s available right now.

Real-World Challenges ADUs Run Into (and How Structure Helps)

1. Tight Lots and Awkward Yards

Plenty of homeowners decide to build an ADU precisely because they live in dense, walkable neighborhoods – which often means tight side yards and tricky access.

Structurally, that might mean:

- Narrow shear walls and carefully detailed openings to keep enough bracing.

- Creative foundation layouts to steer clear of easements and utilities.

- Using engineered lumber or steel where there simply isn’t space for big conventional members.

Those aren’t “extra” features so much as the price of admission for fitting a legal, safe dwelling into a small urban backyard.

2. Older Foundations and DIY Surprises

Garage and basement conversions often start with hidden baggage: thin slabs, unreinforced footings, or improvised framing from past owners.

Structural engineers deal with this by calling for specific upgrades such as:

- Thickening or underpinning footings at key load points.

- Cutting and replacing compromised slab sections.

- Adding new beams or posts to pick up loads when walls are removed.

It’s not glamorous work, but it’s what makes the difference between a space that “looks fine” on day one and one that stays solid for decades.

3. Earthquake, Wind, and Fire-Zone Constraints

If you live in a high-seismic, high-wind, or high wildfire-risk area, your ADU structural requirements will be a bit stricter. That can mean more hold-downs, tighter limits on tall skinny walls, specific roof tie-down hardware, or non-combustible exterior assemblies near property lines.

None of that is optional – it’s how the code tries to protect the people sleeping in that backyard cottage when the weather or ground turns against them.

4. Utility Coordination and Trenching

ADUs usually need new or upgraded utility lines: water, sewer, electrical, sometimes gas. Trenching those lines under or near footings is a structural question as much as a plumbing question.

Your engineer, designer, and utility provider should be on the same page so that trenches don’t undermine foundations or leave heavy loads sitting on fragile pipes.

Building an ADU is exciting, but it’s also a serious construction project hanging off your biggest asset: your home. Trying to wing the structural side with generic plans or guesswork is a risky way to go.

A structural engineering firm is there to translate code language and load paths into clear, buildable drawings. From early feasibility calls through permit-ready structural plans and plan-check responses, the focus is on:

- Explaining what the building code actually expects in plain English.

- Right-sizing foundations, beams, and shear walls so you’re not overbuilding.

- Detailing connections that real contractors can install cleanly.

- Staying responsive when inspectors or contractors have questions in the field.

When the structure is well thought-out from day one, you spend less time fighting with plan check, less money fixing surprises, and more time focusing on the fun parts: layouts, finishes, and how that new space changes daily life for you or your tenants.

Planning an ADU and want experienced eyes on the structural side? Explore our Structural Engineering Services ›

ADU Structural Requirements: Quick FAQ

Do I really need a structural engineer for my ADU?

For most projects, yes. New detached ADUs, second-story ADUs, hillside sites, and garage or basement conversions with major changes almost always require engineered plans. Even where prescriptive code paths exist, having a licensed engineer sign off gives you a much better shot at smooth plan review and long-term peace of mind.

What structural sheets will my building department ask for?

Check your local checklist, but expect to provide at least a foundation plan, floor and roof framing plans, shear wall or bracing layouts, key sections, general notes, and a structural calculation package. Some jurisdictions also want special inspection notes for items like concrete strength tests or structural steel.

How long does the structural part usually take?

Once your floor plan is reasonably settled, it’s common for structural design and drafting on a typical ADU to take a few weeks. Plan-check timelines are more variable – some departments turn around reviews in a few weeks, others can take a couple of months depending on workload. Building in time for at least one correction cycle is smart.

Is a garage conversion easier than a brand-new detached ADU?

It can be cheaper and faster in some markets because you’re reusing the footprint and shell, but “easier” is relative. You’ll still need to prove that the existing slab, walls, and roof can handle their new job. If they can’t, you may be looking at new footings, added bracing, or re-framing – all of which fall right under ADU structural requirements.

What inspections specifically look at structural work?

Most jurisdictions call for: Footing and foundation inspections before concrete is placed. Framing and shear wall inspections before insulation and drywall. Roof, stair, and guardrail checks where those elements are present. Final inspection to confirm the ADU matches the approved, engineered plans. On more complex projects, special inspections may also be required for certain structural steel, concrete, or seismic-resisting systems. Your engineer will note those on the drawings if they apply.

- Author: Perla Irish – Home improvement and remodeling writer focusing on structural upgrades, code-driven projects, and practical guidance for homeowners. Perla writes for Dream Lands Design and contributes to House Sumo, translating “engineer speak” into clear, actionable advice for everyday readers. – View Perla’s Muck Rack profile

- Reviewed by: Ricky McLain, P.E., S.E. – Senior Technical Director at WoodWorks – Wood Products Council. Ricky is a licensed structural engineer with extensive experience in building codes, structural design, and educating design professionals on safe, efficient building systems. – Connect with Ricky on LinkedIn · View Ricky’s professional bio