Will you agree with me If I say the CNC machine is the most important element responsible for manufacturing industries improvement?

I think, yes.

CNC machine is very expensive though you can buy less expensive CNC machining China, which originated in China. They are cheap but provide good performance.

If you already have a CNC machine and looking to improve its efficiency, don’t stop reading.

Our modern world is changing day by day. The manufacturing industry is also changing day by day.

If you compare today’s manufacturing industry with the 1930s, you might see the massive development of the manufacturing industry.

So, what brings the change?

It is lean manufacturing methodology, yeah, you’re reading right.

The advancement of the manufacturing industry solely depends on the lean manufacturing process.

What is lean manufacturing methodology means exactly?

Lean manufacturing is all about improving production operation day by day; what you are doing today will improve that next day.

Besides improving the manufacturing process, a lean framework means the identification of waste and reduce that continuously.

According to lean manufacturing expert, Jamie Flinchbaugh lean technology is all about optimization. Improve today from what it was yesterday, make things better where it was yesterday.

She believes that a lean framework doesn’t mean work faster. Work faster can creates so much error.

Now, a question comes to mind how can I improve the manufacturing process using a lean manufacturing process?

You can improve the manufacturing process by implementing a few key concepts of the lean framework.

Customer value is the number one key concept of lean methodology. Here you need to understand the customer’s mind.

What is most valuable for your customer? What will create a greater impact on the customer? You need to provide these values through improving operations with the help of a lean manufacturing process.

Another thing you can apply is to flow improvement. Flow is all about increasing workflow day by day. In this case, you need to find ways to make the workflow faster.

To achieve that, you can apply a few things such as; make sure that your procedure is simple, keeping your floor organized, and employing the right people in the right position.

And the last thing you can apply is ensuring respect and empowering culture within your business.

Create a culture where everyone from top to bottom feels comfortable with each other for identifying opportunities, improvement, and motivation to fix things and bring changes.

You may hear that skilled people are the real asset. Yes, it’s right for every industry. You can always make your people more skillful so that they can become your asset.

At the first time, it may look like you’re not getting benefits, but in the long run, you would be astonished at the return of investment.

By making people skillful and productive, you’re improving your overall business efficiency. Here are a few things you can implement to achieve this goal and they are;

Start a skill development program for your employees. It will improve their skill and keep them engaged with improvement activities.

The second thing you can do Is to simplify all needed documents for the low-skill worker. Thus, it will result in reducing the error rate.

The third thing you can apply is to start a review or feedback system for employees’ work. You can give it annually. It will help them to understand that you spent on their professional development.

And finally, build a strong culture within your company. Results show that people with a strong culture and happiness tend to deliver greater efficiency in the long run.

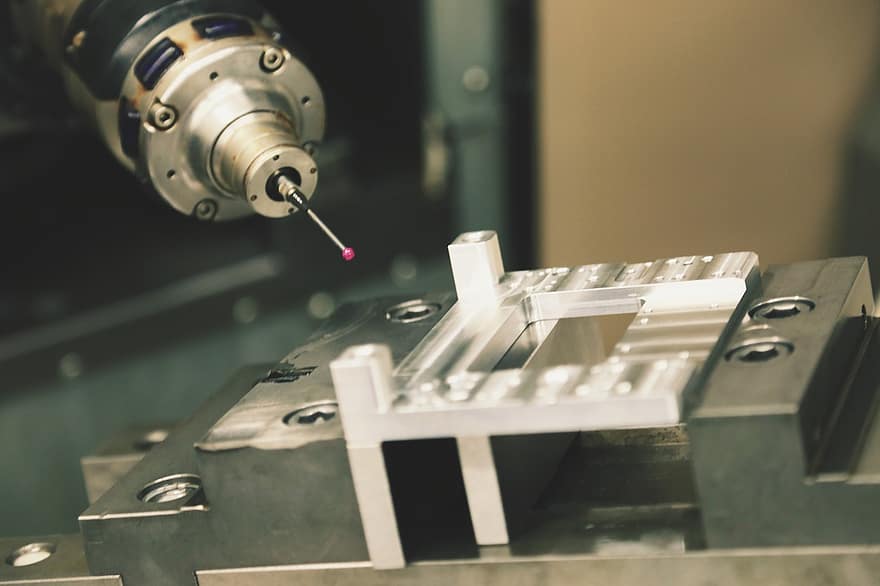

CNC machine is truly a performance beast. They are designed to work fast. They are like formula one racing car. Push them as fast as possible.

The modern days CNC machines can work at a very faster speed. Now they are capable of completing more tasks in a short time.

This machine is a profitable asset in your shop. First thing you should ensure that it runs all the time. Make sure that it can always remain on duty. Therefore, it will make more money for you.

Did you ever try to figure out or improve cycle time?

It is the most important thing you can do to improve your business efficiency. You will be surprised to know how much production improvement is possible through cycle time improvement?

If one second is saved in a cycle, in a thousand cycles production’s total saved time will be 16.6 minutes.

Moreover, if four seconds are saved in a cycle, then the saved time will be one hour for one-thousand-piece production per cycle.

Isn’t it cool?

Here I discussed the 4 most efficient tips that are proven for bringing changes in the manufacturing process. If you implement the above suggestion, I hope you would see considerable improvement.

Best of luck!